Corporate world is very dynamic where the role of the operations department is very crucial to sustain growth and success. They manage all the relationship between different corporate functions to guarantee smooth operations and maximum effectiveness.

Top challenges companies face includes unclear goals and scope (64%), poor planning (57%), and communication issues with stakeholders (56%). But sometimes they struggle to handle those operations systematically and that’s when they need help of something that can make their work systematic.

OKR is one such tool which is very effective and systematic when it comes to alignment and visibility of the goals. It is basically a framework that is widely used by organizations to align and measure the success of their objectives.

It provides a structured and transparent way for teams to set, communicate, and monitor their goals. More than 80% of businesses surveyed agreed that OKRs benefit their company.

Okr Challenges for Operations Teams

There are multiple challenges faced by the operations teams:

- Resource Constrains

- Technological Challenges

- Quality Control Issues

- Low Productivity

- Logistical Delays

How OKR can solve these challenges

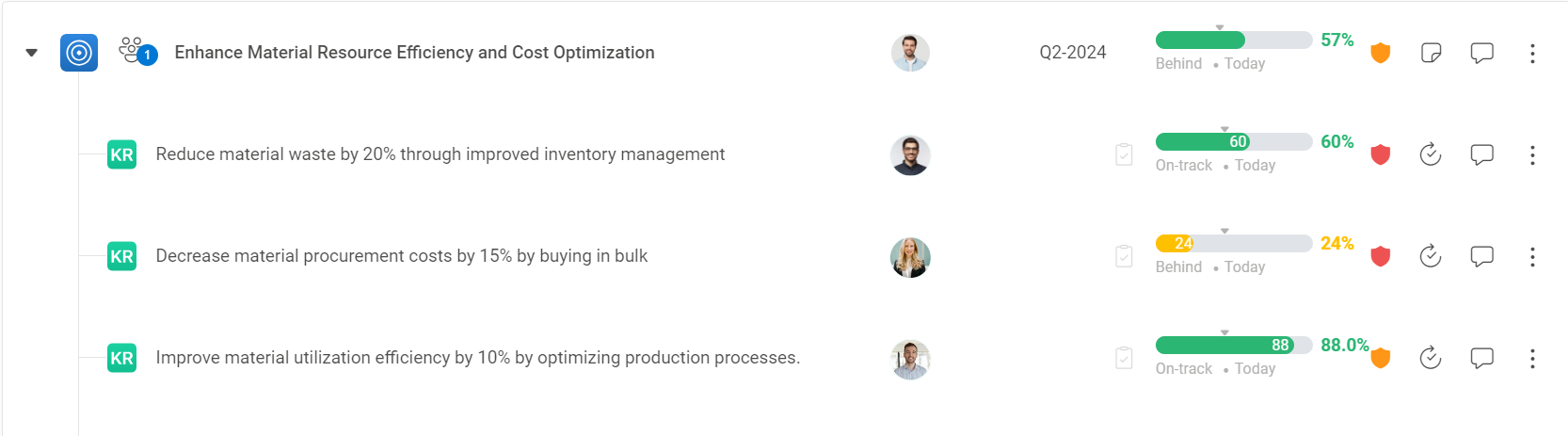

1. Resource Constrains

Operations teams face several problems when dealing with resource limitations, which affects their productivity and capacity to meet company goals.

According to study insufficient resources are the fourth most popular reason for project failure (52%), including both human and material resources, frequently lead to decreased overall efficiency as groups struggle with increased workloads and postponed project deadlines.

Teams that are understaffed or insufficiently equipped may experience quality compromises, which can raise error rates and lower the standards of the goods or services produced.

OKR can become a strategic solution for the operation teams with limited resources. Despite scarce resources, OKRs help teams concentrate on high-priority tasks by offering a clear framework for goal setting. Because Key Results are observable, wasted effort is minimized and resources are targeted effectively to projects that directly contribute to overarching objectives.

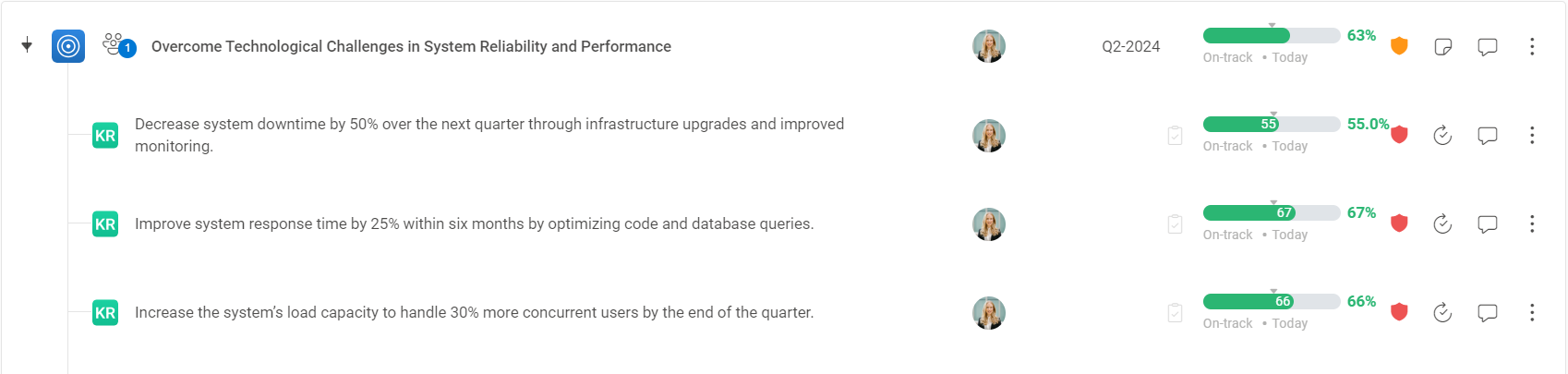

2. Technological Challenges –

Several technology issues that operations teams face can have a big influence on their productivity and effectiveness. Outdated technological infrastructure presents a concern since it slows down operations and makes it harder to adjust to changing business requirements.

Problems with system and tool integration can lead to data disparities and make it more difficult for the team to have a complete picture of operations. Sensitive operational data is at risk from cybersecurity threats, which could result in breaches and interruptions.

Operations teams can address their technical difficulties in a strategic way by implementing OKRs. OKRs offer an organized framework that promotes alignment between overarching business objectives and technical goals.

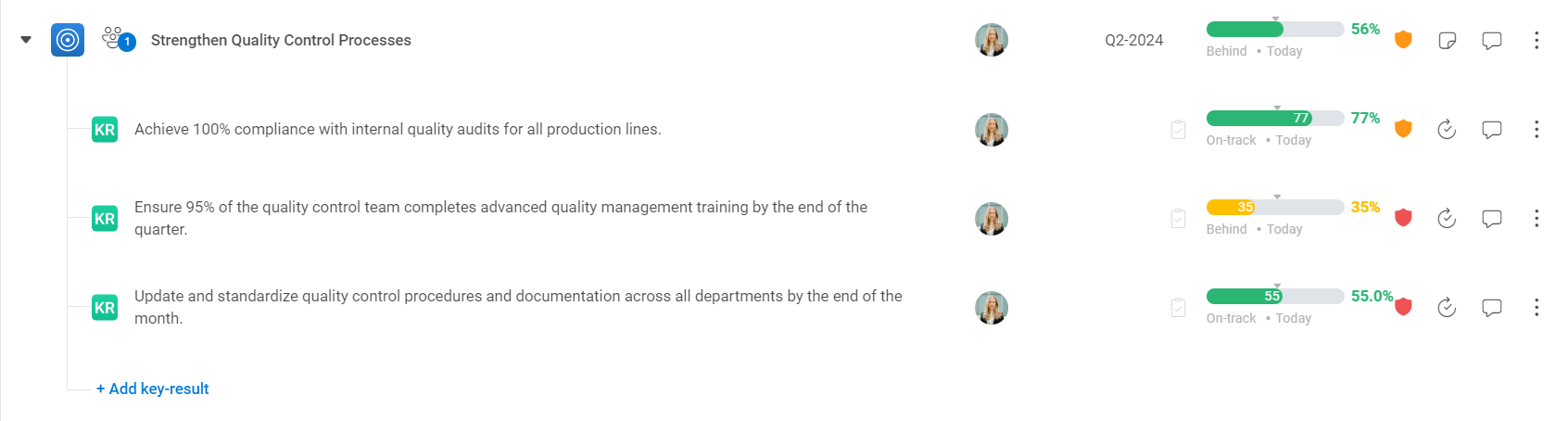

3. Quality Control Issues-

Operations teams frequently deal with several kinds of quality control problems that can seriously harm a company’s reputation and general productivity. Poorly defined quality measures and inconsistent standards can lead to inconsistent product or service quality, which can lower customer satisfaction and possibly harm a brand’s reputation.

According to a study companies spend around 15% to 20% of their sales revenue on quality-related expenses. Sometimes, these costs for poor quality can even go up to 40% of all operations.

Implementing Objectives and Key Results (OKRs) provides a strategic framework to effectively address and resolve quality control issues faced by operations teams.

OKRs can play a pivotal role in enhancing quality by instilling a culture of accountability, continuous improvement, and clear communication. Objectives related to standardizing processes, defining clear quality metrics, and implementing robust training programs can address inconsistencies in quality standards and reduce the likelihood of errors due to insufficient training.

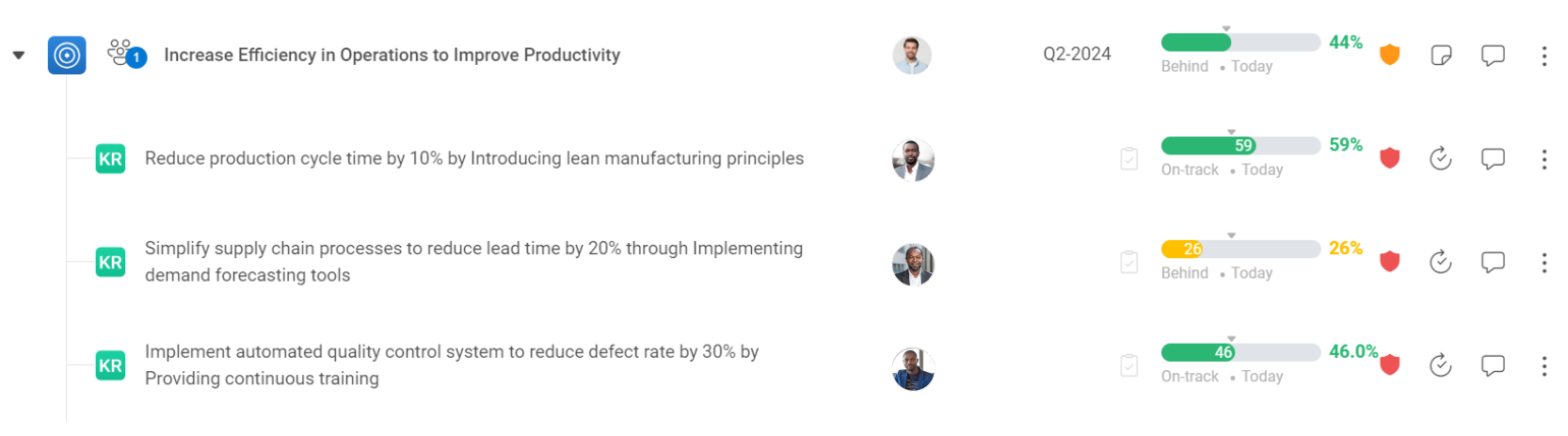

4. Low Productivity-

Low productivity is a common problem for operations teams, which affects their effectiveness and general performance. Bottlenecks and delays are caused by poor resource allocation, ineffective procedures, and a breakdown in clear communication lines.

Further impeding productivity are team member weariness, resistance to change, and inadequate training. A recent HubSpot study found that employers lose approximately $1.8 billion each year due to low productivity.

Operations teams can use OKRs as a strategic strategy to address issues with low productivity. It offers a goal-oriented method to increase productivity by defining precise, quantifiable objectives and connecting them to certain key results.

The OKR framework’s repeated reviews and adjustments create a continuous improvement culture by empowering teams to spot and fix bottlenecks. In addition, OKRs encourage transparency and communication, which makes sure that everyone in the team is working toward the same overall objectives. This increases morale and output.

5. Logistical Delays-

Operations teams face several difficulties linked to delays in logistics, which affect how well processes operate. Transportation-related concerns, such as shipping delays, customs clearance delays, or supply chain logistics interruptions, are frequent issues.

Delays can be made worse by faulty forecasting, poor inventory management, and poor supply chain coordination and communication.

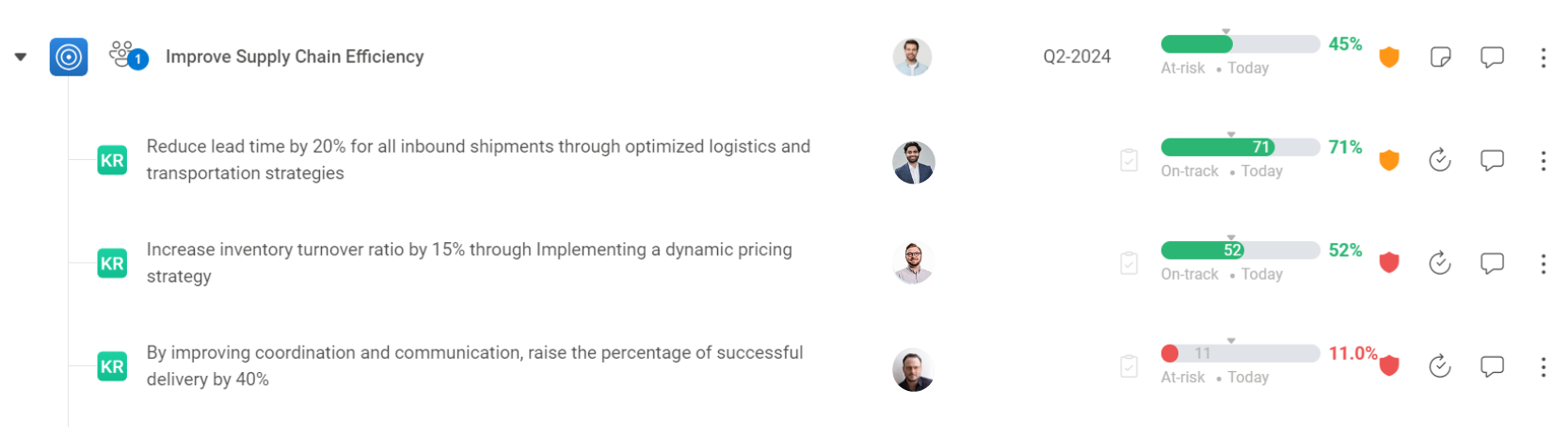

Operations teams may address logistical delays with a strategic approach by utilizing OKRs. OKRs offer a targeted improvement framework by defining specific targets such as “Minimize shipping delays” or “optimize supply chain efficiency” and tying them to measurable key results.

Teams can detect and address problems quickly because of the ongoing optimization of logistics operations made possible by the OKR methodology’s regular assessments and modifications.

Conclusion:

OKRs can be a powerful tool for operations teams to achieve operational excellence and address various challenges they face. By setting clear, measurable objectives and key results, teams can focus on high-priority tasks, optimize resources, improve productivity, and enhance quality control.

OKRs also help in addressing technological challenges, low productivity, and logistical delays. The examples will help you to understand how OKRs works.

Ready to streamline your operations and overcome challenges with ease?

Worxmate’s OKR Tracking Software helps operations teams set clear objectives, track progress in real time, and drive measurable results. Boost efficiency, optimize resources, and achieve operational excellence—effortlessly!